The purpose of this article is to identify some of the brick and tile manufacturing works in south west Durham, particularly those in and around Evenwood, Evenwood Gate and Ramshaw.[1] It will comment on:

- The brick works at Randolph, Evenwood.

- The brick and tile works at Evenwood Gate and Hilton Tarn near Wackerfield.

- Other brick work sites in the Gaunless Valley at the Slack and Butterknowle and possible sites at the Gaunless Lead Mill, Low Lands and Norwood Colliery.

- Other brick works with associations to colliery companies with connections to Evenwood and Ramshaw.

- The last 2 surviving brick works in the Bishop Auckland area at Eldon and Todhills, only one of which is currently operating.

This is not an authoritative account and it is an open invitation for others to comment.

1. INTRODUCTION [2]

Most of us live in a house made of bricks with a tile roof with drains taking away waste water and sewerage. All of these products are made from clay or shale deposits which occur widely throughout County Durham, either at or near the surface or are part of the coal seams below ground. With the growth of towns and villages in the 19th century, the need for bricks, tiles and pipes was enormous and hundreds of brick and tile works were built throughout Durham to satisfy this demand.

Iron and steel works, coke ovens and furnaces required specialist refractory and fire bricks. The extensive deposits of ganister and fire clay, usually located immediately below coal seams, provided a raw material easy to obtain at economical cost, close to the point of use.

There are several kinds of bricks, each having their own specialist use:

- Common Bricks: these are used for inside work or side walls where appearance is not important.

- Facing Bricks: High quality bricks visually attractive, sometimes with a pattern or rustic finish, used on the outside of houses.

- Engineering Bricks: Very hard bricks for structures like bridges and viaducts.

- Refractory and Fire Bricks: heat resistant bricks used in coke ovens.

- Paving Bricks: A short lived substitute for stone or concrete paving stones in the 1920s, now enjoying a revival for pedestrian shopping centres and patios.

In addition to brickworks, there were many specialist tile and pipe works making roofing and ridge tiles, drain pipes for houses and farm land. The manufacturers sometimes made a variety of other products such as chimney pots, sinks, toilet fixtures, cattle troughs and garden ornaments. Sanitary ware would be glazed for hygienic reasons, using a salt glaze in the firing process.

Initially, bricks were hand-made and were irregular in shape and texture, slimmer than today. They were made in moulds and often had a hollowed out portion on the upper face called a frog. This, when filled with mortar by the bricklayer, helps bond the brickwork.

As manufacturing processes developed, bricks sizes were standardised. The pre-metric, imperial measurements, in inches, for a brick were, 9” x 4½” x 3”. Bricks usually had the name of the manufacturer or initials moulded into the bed of the brick.

The following list of manufacturers represent some of the many that operated in south west Durham, usually in association with collieries. The initials highlighted below are those commonly found on the bricks manufactured here:

Bolckow: Bolckow & Vaughan

B & V: Bolckow & Vaughan

BV WP: Bolckow & Vaughan (Witton Park)

BV AP: Bolckow & Vaughan (Auckland Park)

BV BG: Bolckow & Vaughan (Byers Green)

BV N: Bolckow & Vaughan (Newfield)

BV LC: Bolckow & Vaughan (Leasingthorne Colliery)

C & M: Chapman and Morson, Crook

HS: H. Stobart

HS & Co: H. Stobart & Company

J HOGG: John Hogg, Witton Park

NC: Newton Cap, Toronto, Bishop Auckland

N CAP: Newton Cap, Toronto, Bishop Auckland

NB: North Bitchburn Coal Co. Ltd., North Bitchburn and Rough Lea, Hunwick

NORTH BITCHBURN COAL CO LTD DARLINGTON: North Bitchburn Coal Co. Ltd., North Bitchburn and Rough Lea, Hunwick (main office was at Darlington)

PEASE: Pease & Partners, Crook

RANDOLPH: Randolph Brickworks, Evenwood

STOBART: H. Stobart & Company

TC & Co: T. Charlton & Co., Bitchburn

A number of photographs are included at Appendix 1 to show examples of the above.

2. THE EVENWOOD AREA

There are 3 documented brick works sited in or near to Evenwood. They are:

- Randolph Brick Works at Randolph Colliery, Evenwood operated by the Summerson brothers, which worked from the 1930s to 1958.

- The Hilton Tarn brick and tile works, Wackerfield operated by John Pescod which worked from about 1856 but was closed by 1871.

- Evenwood Gate brick and tile works c.1898.

2.1. RANDOLPH BRICK WORKS, EVENWOOD 1930s – 1958 [3]

The brick works, located to the south of Randolph Colliery, Evenwood, was operated by William and Maurice Summerson, who also owned Randolph Colliery and other collieries at Gordon House (Cockfield), the Ramshaw group of collieries (Copeland Bank, Gaugers Arms, Spring Gardens and Ramshaw Heugh) and Whitworth Colliery (Spennymoor).

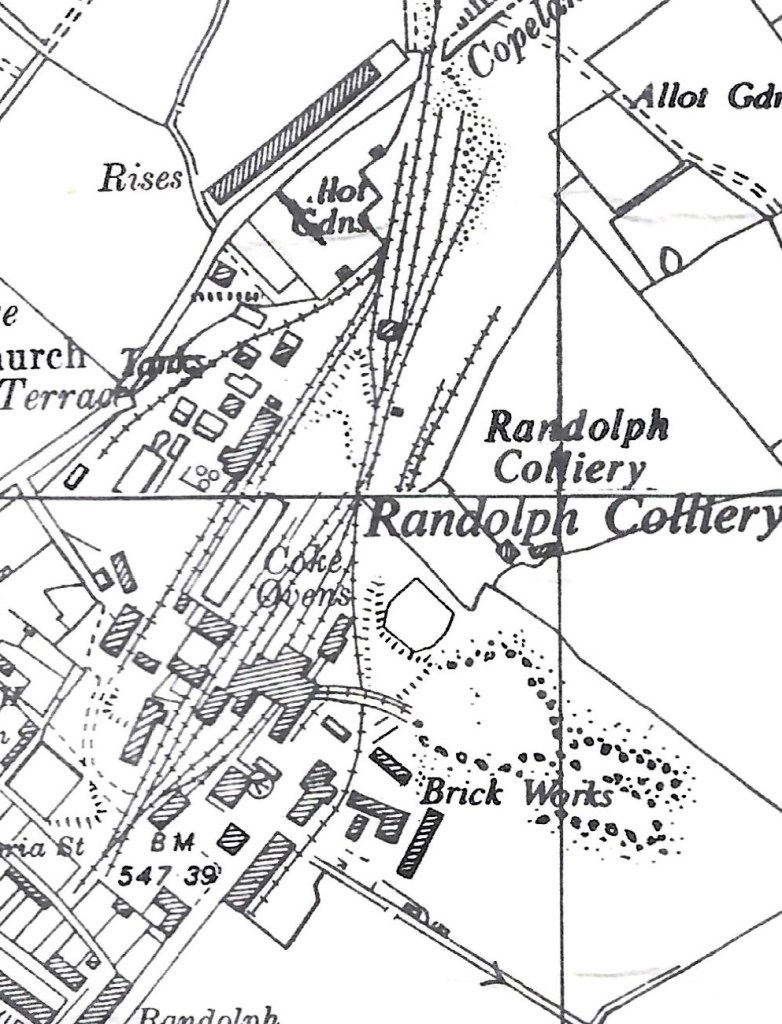

Above: 1953 OS Map to show Randolph Brick Works

The following is a description of Randolph brickworks:[4]

“Randolph Colliery brickworks, Evenwood was opened in the early 1930s and made common bricks from the colliery shale. Seggar from the Hutton seam produced a red coloured brick while shale from other seams produced less attractive off-whites and browns. Reject bricks were ground down in the mill and added to the clay as grog. This was done especially during wet spells in winter when the clay in the pug mill mixer got too soft i.e. the grog tended to soak up the excess moisture.

The yard had 16 Newcastle kilns, each one capable of holding 14,500 bricks. Six of the kilns each had their own separate chimneys which were only about 20 ft. high, while the rest of the kilns were connected up to one big chimney.

Each kiln was fired through 3 fire holes at the front and during the latter stage of burning, coal was also fed in through the vent holes in the kiln roof to achieve top heat throughout the setting in the kiln. In addition to sight, the burner judged if the bricks were properly burned by the contraction of the setting. This was done by resting a firebrick shape on top of the setting so that one end of the brick stuck out through one of the vent holes in the kiln roof by about 4 inches. As the bricks contracted the brick showing through the vent hole slowly sunk until the top of it went out of view, at which time the bricks were thoroughly burned.

Many brick were sent to Catterick Camp and for Crook Urban District Council. Before the Second World War 2 shifts were working here but after the war only a day shift was working. Mr. W. Summerson retained the ownership of the brickworks after nationalisation of the colliery. The brickyard closed in 1958 with the loss of 16 jobs.”

Above: A Randolph red facing brick

In 1939, William Summerson of Highway, Etherley was described as a, “Colliery Director” and his brother Maurice Summerson of Hilton Lodge, Evenwood Gate was recorded as, “Managing Director to five colliery companies.”

At this time, within the Evenwood ward, 2 men, George Vickers (Evenwood Gate) and William Taylor (The Green) were described as “enamel stone (hospital) sanitary fireclay moulder” and “moulder sanitary ware” (respectively).[5] Shaw Knight Co. Ltd., located at Tindale Crescent produced enamel sanitary stone ware therefore these men could have worked there. This suggests that there were few Evenwood men employed in brick manufacture. If Randolph brick works had been established in the 1930s, it would be likely that local men would be employed there. Perhaps by 1939, it had been “moth-balled” due to lack of demand due to the worsening political climate in Europe. Perhaps, the company had not commenced large scale production at this time.

2.2. HILTON TARN BRICK AND TILE WORKS NEAR WACKERFIELD

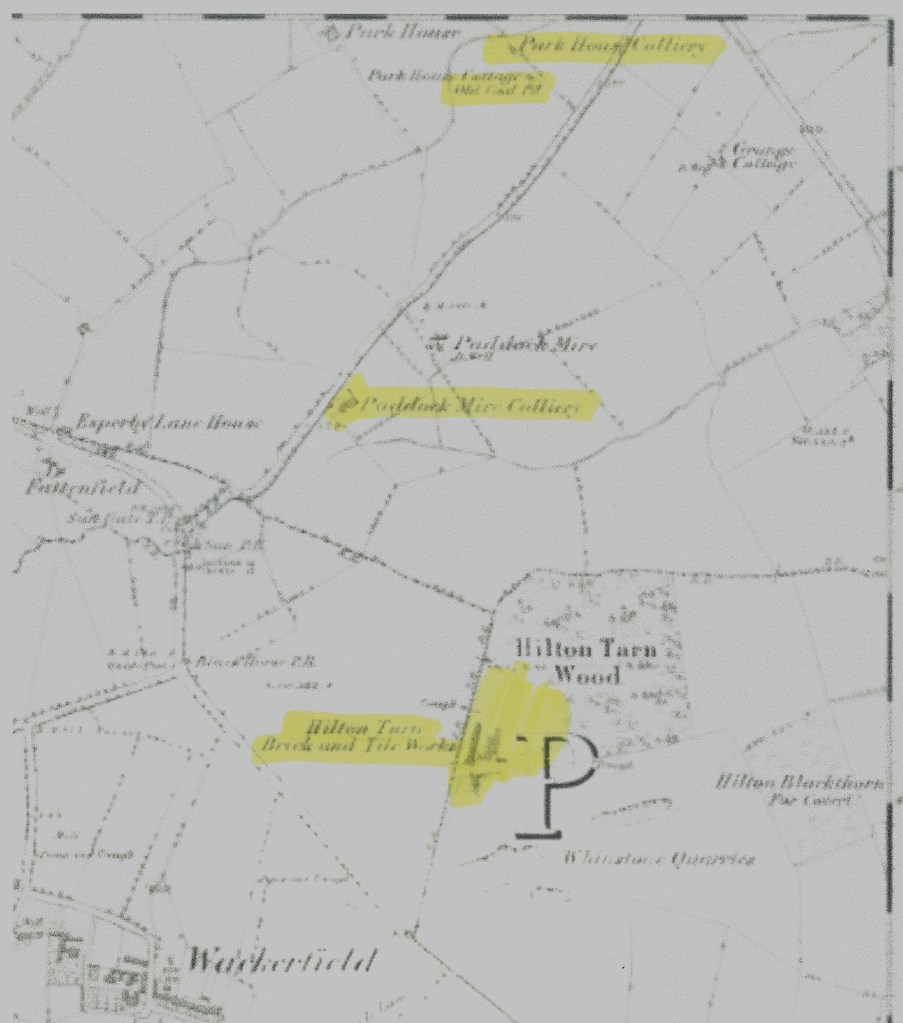

The first 3 editions of the Ordnance Survey, 1859,[6] 1898 and 1914, show locations of potteries, brick and tile works and small collieries. They are:

- New Moors Pottery [7]

- Hilton Tarn Brick and Tile Works [8]

- Park House Colliery

- Park House Cottage, old coal pit

- Paddock Mire Colliery [9] sunk in 1845, closed 15 February 1853

- Evenwood Gate Brick and Tile Works[10]

- Sun Colliery

The small coal workings at Park House, Paddock Mire and Sun Collieries may have found a local market for fireclay at New Moors Pottery, Hilton Tarn and Evenwood Gate brick and tile works. There is a post relating to New Moors Pottery elsewhere on this website.

The Hilton Tarn Brick and Tile Works was located to the north east of Wackerfield. John Pescod (1811–1876) from about 1856 operated this business.[11] The 1861 census for Wackerfield records that John Pescod was a brick manufacturer. His wife May and 3 sons Joseph, Thomas, George and 2 daughters Thomasina and Lavinda also worked there. Other workers were Richard Robinson who was recorded as a tile maker, Robert Bowes and his sister Isabell who were both brick makers.

By 1871, John Pescod had moved away from Wackerfield and lived at Hunwick. No trade was attributed to his name. With regard to his sons – Joseph Pescod was a brick maker at North Bitchburn, Thomas was a colliery agent living at Witton-le-Wear and George was a brick maker at Witton-le-Wear. With regard to other workers – Robert Bowes had moved out of the area and was a brick burner at Baildon in Yorkshire; Richard Robinson has not been traced. No other men or boys were recorded as working in the industry in the Wackerfield or Evenwood & Barony Parish at this time. Therefore, by 1871, it is assumed that the brick and tile works at Hilton Tarn was not working.[12]

Above: The 1859 OS map to show Hilton Tarn brick and tile works, Park House and Paddock Mire Collieries

The Hilton Tarn brick and tile works was not named as such on the 1898 OS map.

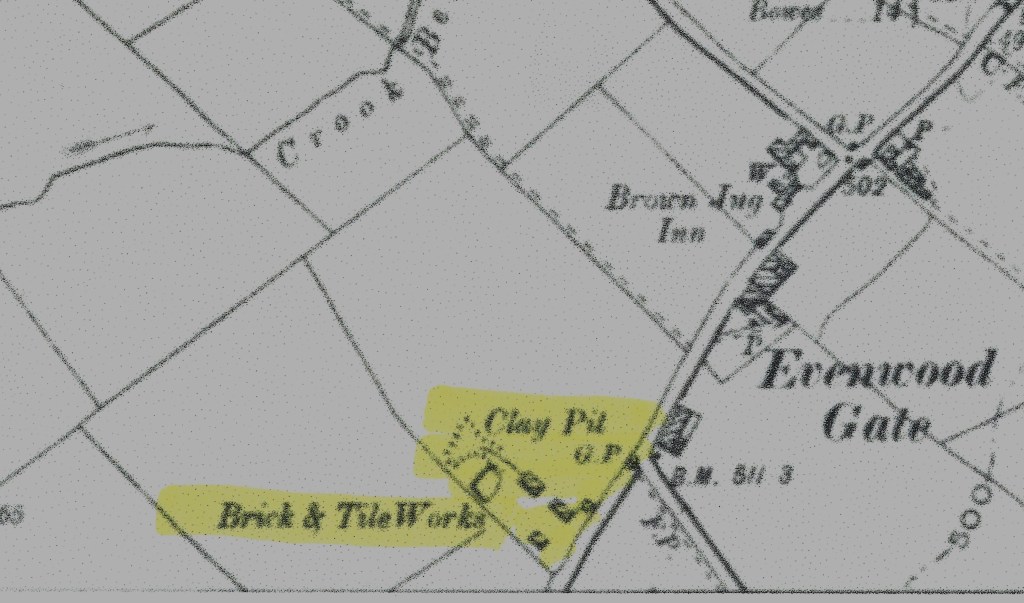

2.3. EVENWOOD GATE BRICK AND TILE WORKS

The brick and tile works was located to the south west of Evenwood Gate and opposite the road junction with Hilton Moor Lane. It consisted of 4 buildings and a clay pit .[13] No men or boys within the Parish of Evenwood & Barony were recorded as working in the industry for the years 1891 and 1901.

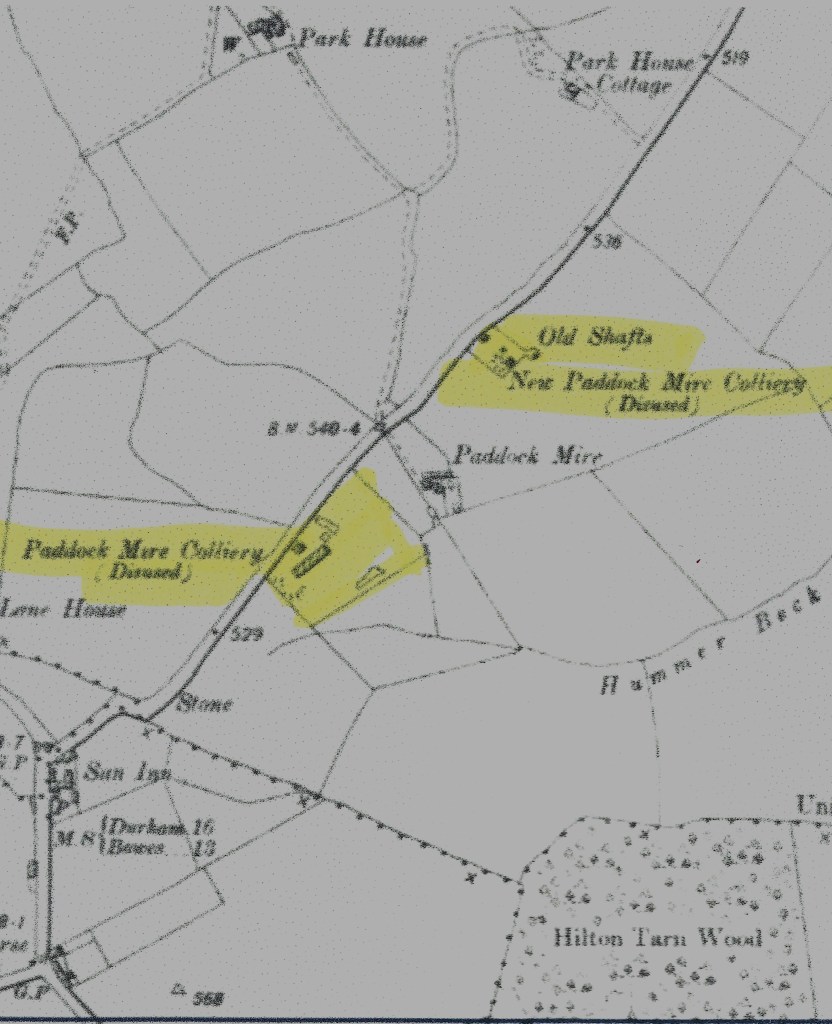

The 1898 OS map shows 2 disused collieries:

- New Paddock Mire Colliery which had 2 buildings and old shafts

- Paddock Mire Colliery which had 2 buildings [14]

Above: The 1898 OS map to show Evenwood Gate Brick and Tile Works and disused collieries

The 1914 OS map describes the site of the 1898 Evenwood Gate Brick and Tile Works as Park House Cottage thus it is assumed that it had stopped working by then. The site of the former Paddock Mire Colliery was called an, “old pottery.”[15] In 1908, Tom Robinson of Wackerfield worked at Paddock Mire Pottery. As a young lad, he earned 9d per day for being in charge of the horse driven pug mill.[16]

The 1914 OS map shows a new colliery, the Sun Colliery located to the immediate east of the Sun Inn public house.[17] It was worked by a shaft and a drift and was probably closed by 30 July 1914 when details of the sale of colliery gear was advertised in a local newspaper. This colliery may have provided coal and fireclay for the Evenwood Gate Brick and Tile Works.

Currently, in October 2024, the site of the Evenwood Gate Brick and Tile Works is uncultivated land, partly under water – a pond occupies some of the site.

The site of the Hilton Tarn Brick and Tile Works is currently a farm holding.

3. THE GAUNLESS VALLEY

There are 2 known brick works:

- The Slack to the west of East Butterknowle Colliery

- Butterknowle brick works

And 3 others where evidence is less certain:

- Gaunless Lead Mill Brick and Tile Works

- Low Lands brick works

- Norwood Colliery, Ramshaw

3.1. THE SLACK, WEST OF EAST BUTTERKNOWLE COLLIERY

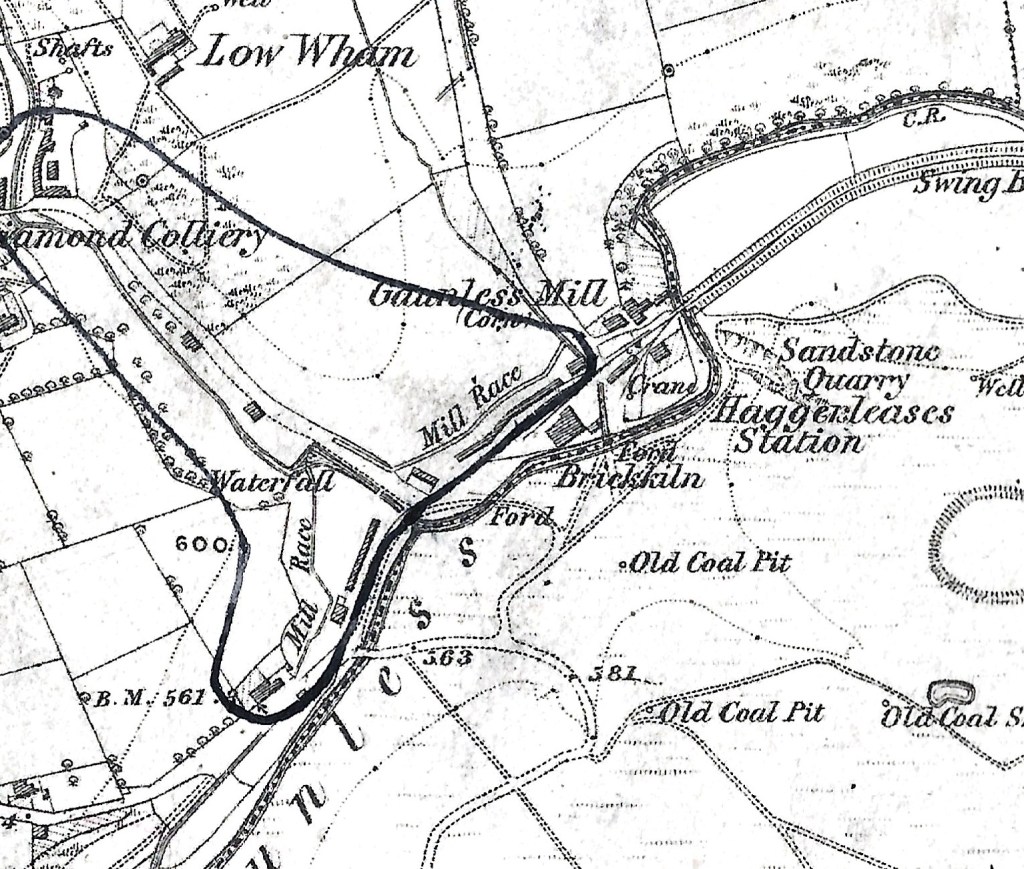

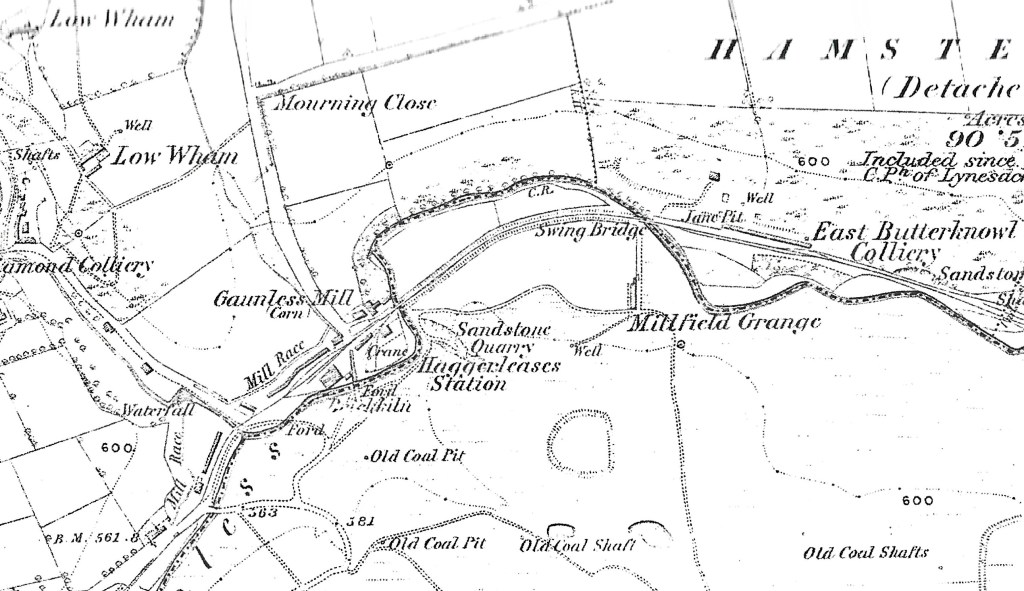

East Butterknowle Colliery and the coke ovens was located along the Haggerleases branch railway, some 2 miles west of Evenwood. A brick kiln was located further to the west and south west of the Haggerleases Station, north of the river.

Above: 1859: Map to show the brick kiln to the south west of Haggerleases Station [18]

Above: A model of the Haggerleases Station, later known as Butterknowle Goods Yard. The brick kiln would have been west of the road, to the left of the model.

Bricks found in the vicinity of the coke ovens bear the name J. HOGG. Also impressed on the right hand corner of the bed is a thumb print. These bricks are tapered and show evidence of firing – mineral deposit is caked on the smaller end.

Above: A pair of J. HOGG bricks found in the vicinity of the coke ovens at East Butterknowle Colliery

It seems probable that John Hogg of Witton Park sourced bricks for the East Butterknowle Colliery coke ovens. The 1856 Whellan’s Trade Directory records “Pickard & Hogg” firebrick manufacturers of Witton Park. These 2 men are likely to be:

- James Pickard (1807-1881) [19] He was born at Wakefield, Yorkshire. In 1841, he was recorded living at Shotley Bridge, County Durham and employed as a, “Brick Manufacturer.” By 1851, he and his wife Jane lived at Sunny Side Park, near Billy Row, Crook with 6 children. James was recorded as a, “Brick Manufacturer employing 34 labourers.” By 1861, James and Jane lived at Wolsingham with their son John. James was described as a, “Fire Brick Manufacturer employing 13 men and 6 boys” and their son, John was recorded as a foreman.

- John Hogg (1823-79)[20] He was born at West Auckland. In 1861, he lived at Queen Street, Witton Park and was recorded as a, “Brick Manufacturer employing 22 men and 10 boys.” John lived with his wife Elizabeth and 7 children. Previously, in 1851, he was employed as the Station Master (Witton Park) and afterwards in 1871, he was the innkeeper of the “Queens Head,” Witton Park.

Demand for coke was provided by Bolckow Vaughan & Co. in order to supply the iron works furnaces at Witton Park which operated from 1845 to 1884. Construction commenced in 1845 and blast furnace no.1 was operational the following year. An output of 1,100 tons per week was produced.[21] At East Butterknowle Colliery, by 1854, 33 coke ovens were fully operational and production was 7,000 tons of coke and 20,000 tons of coal.[22] Witton Park Iron Works was reduced by 1878 when it was partly shut down as production of iron and steel moved to the banks of the River Tees. It was finally closed 19 May 1884.[23]

The 1859 OS Map shows East Butterknowle Colliery, located close to the Haggerleases Branch Railway. Jane Pit is named and a line of coke ovens is indicated. The 5-mile branch line, which ran from West Auckland to Haggerleases Station, was operated by the Stockton and Darlington Railway Company Ltd. and opened in October 1830.[24]

1859: East Butterknowle Colliery in relation to the Haggerleases Branch

Above: 2023 Remains of East Butterknowle Colliery coke ovens

The ownership of the brick kiln is unknown. There are 2 possible owners:

- John Hogg could have established a manufacturing base near to the coke works site. It is understood that John Hogg was in partnership with John Hymer and Joseph Teasdale as firebrick manufacturers about 1860.[25] In 1851, a John Hymer lived at Haggerleases Lane, He was recorded as a, “Ironstone Contractor.”[26] To date, a likely local candidate for Joseph Teasdale has not been identified even though the Teasdale family name is common to the area.

- Fenwick Pescod (1824-99) The Pescod family was associated with brick manufacture in County Durham. It is known that Fenwick Pescod was at Cockfield around 1855.[27] The census provides evidence. In 1841, Fenwick lived with his parents George and Margaret Pescod at Witton Park where his father worked in the brick manufacturing industry. By 1851, Fenwick, his wife Hannah and 2 children lived at “New” Bitchburn, North Bitchburn where he worked as a brick maker’s labourer. By 1861, he and his family lived at Helmington Row, a colliery village located between Crook and Willington. Fenwick, then 37 years old, was described as a “Brick Maker.” It is recorded that his 6 years old son George was born at Cockfield about1855. His daughters Margaret (aged 9) and Sarah (4) were born at Crook & Sunnybrow respectively, thus, the Pescod family could have lived at Cockfield between 1852 and 1857. They were definitely at Cockfield in 1855. These dates are within the timeframe for the Witton Park ironworks and when coke was manufactured at East Butterknowle Colliery. After North Bitchburn, Fenwick Pescod and his family moved to Thistleflat (Crook), Willington, Lanchester and Cornsay Colliery. Fenwick’s younger brothers Robert (bc.1837) Lancelot (1839-1887) and George (bc.1841), were all born at Witton Park and were all associated with brick manufacture in the Crook area. To the best of our knowledge, no Pescod bricks have been found locally.

There were at least 4 other men with the Pescod surname working in the industry in County Durham:[28]

- John Joseph Pescod (born about 1825 at Swallwell) worked at Lanchester (1851) Consett (1861 & 1871) and Durham City (1881).

- Lancelot Pescod (1817–1855) was born at Whickham and in 1851 lived at Wolsingham employing 15 men and boys at the brickworks at the Marshall Green Colliery near Witton-le-Wear.

- His brother, John Pescod (1811–1876) from about 1856 worked the brick and tile works near Wackerfield (see above).

- Another John Pescod made bricks at Aykley Heads, Durham.

Back to Butterknowle and the 1861 census for the Lynesack & Softley Parish, records the following 6 men employed in brick manufacturing in some capacity:

- Christopher Wilson living at Howle and recorded as a brick manufacturer

- William Parkin living at Water Gate Eye, brick maker

- Thomas Hymer living at Copley Bridge, brickyard labourer

- John Gibbon living at Lanehead, brick moulder

- John Clarkson living at Yard Road, brickyard labourer

- William Chapman living at Brunt Hill, brickyard labourer

Of these, 2 men, Christopher Wilson (1834-1904) and William Parkin (1831-1906) were employed for a reasonable length of time. Christopher Wilson[29] for at least 30 years and William Parkin[30] for at least 20 years. The other 4 men did not stay in brick manufacturing work. Later:

- Thomas Hymer (c.1810-1884) was employed as a coal miner, locally.

- John Gibbon (bc.1842) moved to Willington and worked as a coal miner.

- John Clarkson (c.1846-1910) moved to Darlington.

- William Chapman (c.1848-1929) worked locally as a coal miner.

No employment in brick manufacture was recorded at Lynesack & Softley in the 1891 census.

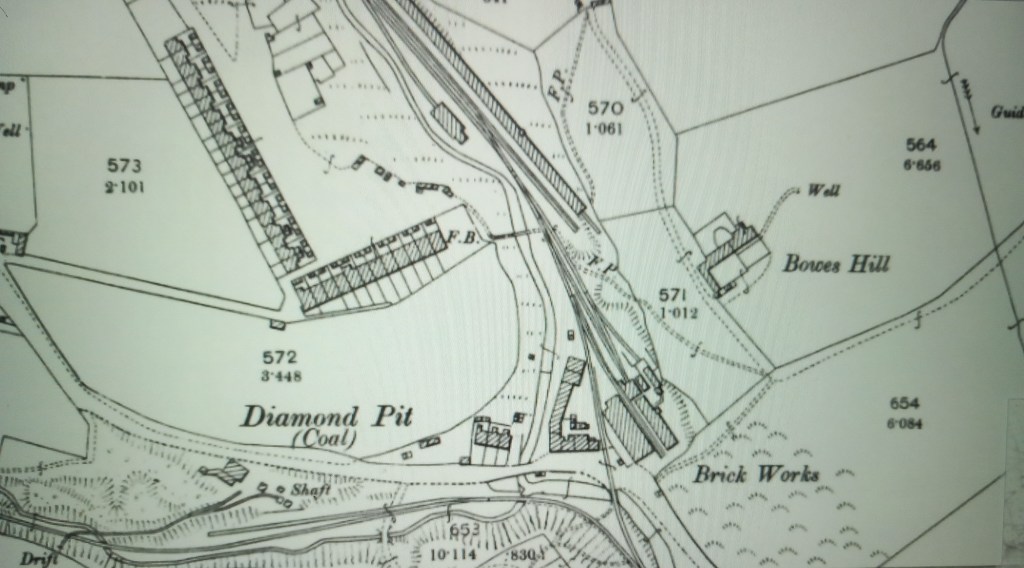

3.2. BUTTERKNOWLE BRICK WORKS

Butterknowle brick works was located on land to the north of the Slack and the road leading up Diamond Bank into the village. Butterknowle bricks were used for the construction of the new coke ovens which were to the immediate north, along Crowe Howle Beck.

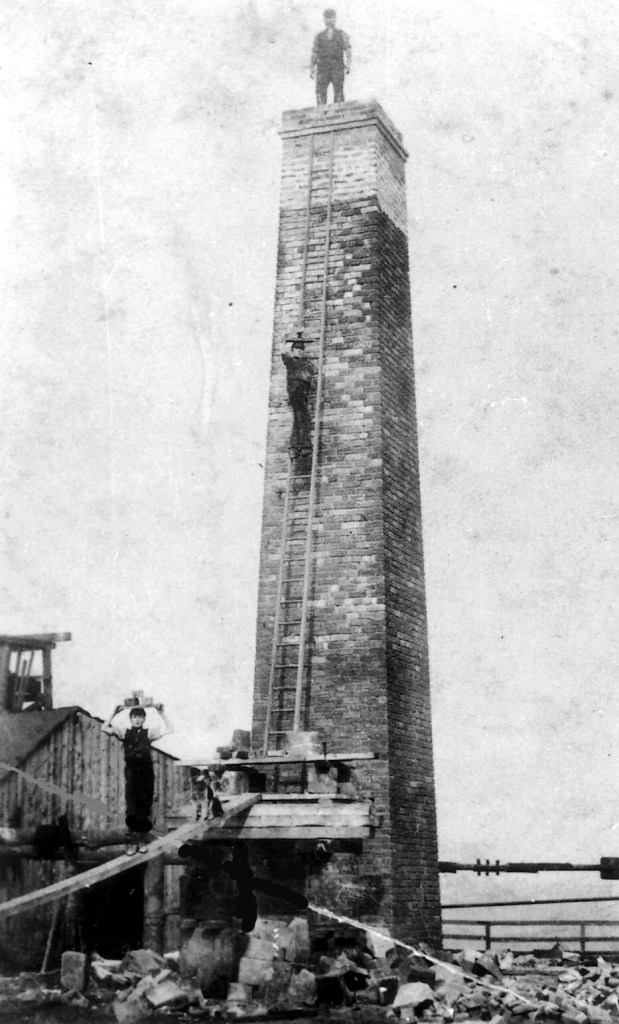

Above: A view of the Slack with the 2 chimneys of Butterknowle brick works standing tall.

Above: 1898 OS map to show Butterknowle Brick Works in relation to the coke ovens

The development of this coke works was probably the main reason for the brick works being established. It is understood that Butterknowle brick works worked between 1894 and 1924.[31] The level of employment was relatively low. The 1901 census for the Lynesack & Softley Parish records only 4 boys employed in the brick manufacturing business. All 4 boys, Thomas Allison, Thomas Blackett, Michael Marr and Thomas Peairs were brick yard labourers. The census for 1891 and 1911 show that no-one was employed in this industry within the Lynesack & Softly Parish or the neighbouring Cockfield Parish.

Above left: Raising the height of one of the chimneys – no Health & Safety considerations in those days! [32]

A Butterknowle brick is distinguished by a thumb print on the right hand side of the bed. An example is provided below. Tapered bricks were used in coke ovens. Similar bricks have been found at East Howle, north of Ferryhill, County Durham.[33]

Above: A Butterknowle brick

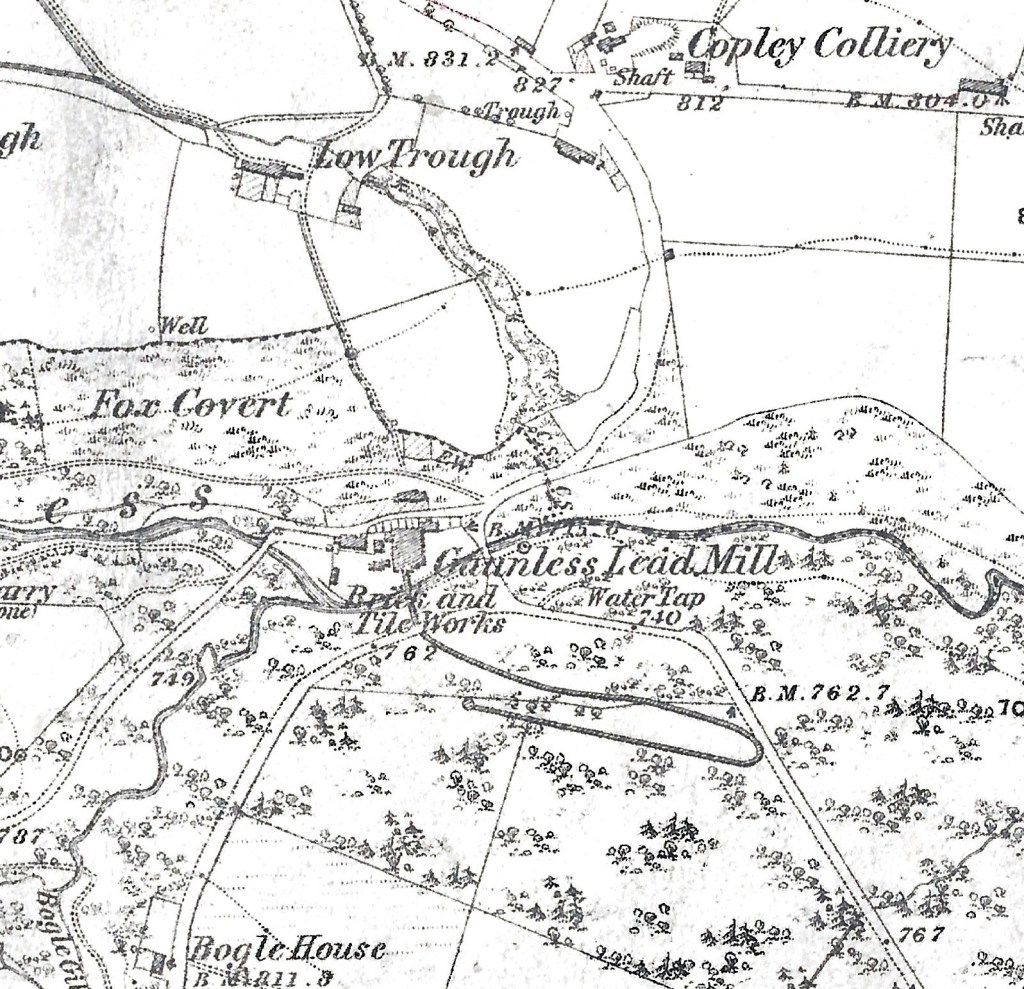

3.3. THE GAUNLESS LEAD MILL BRICK AND TILE WORKS

The 1859 OS map names a brick and tile works to the south of Copley Colliery. The prime manufacturing process at the site was a lead smelting mill. An impressive chimney remains to this day which is constructed with a stone outer skin and brick inner. The OS map indicates a track (or is it a flue) connecting the brick and tile works to the chimney. Was this a brick works? Perhaps the works was established to provide bricks for the chimney?

Above: 1859 OS Map to show the Gaunless Lead Mill brick and tile works

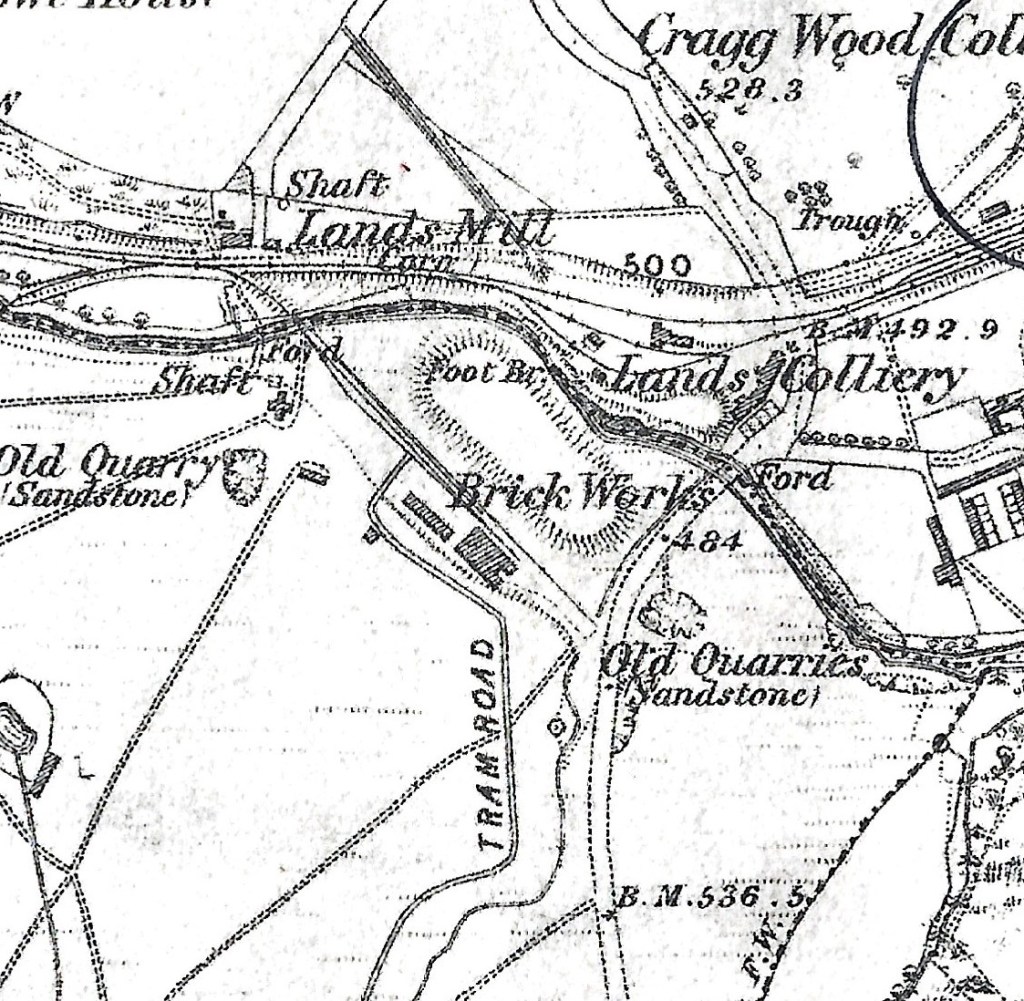

3.4. LOW LANDS BRICK WORKS

The industrial area was at Low Lands near the River Gaunless and the railway sidings.[34] The 1859 OS map shows a brick works to the south of the River Gaunless and Lands Colliery. The 1851 census for Lynesack & Softley and Cockfield Parishes record no men employed in brick manufacture.[35] If this works existed then it was a short lived commercial venture.[36]

Above: 1859 OS map to show the brick works at Low Lands

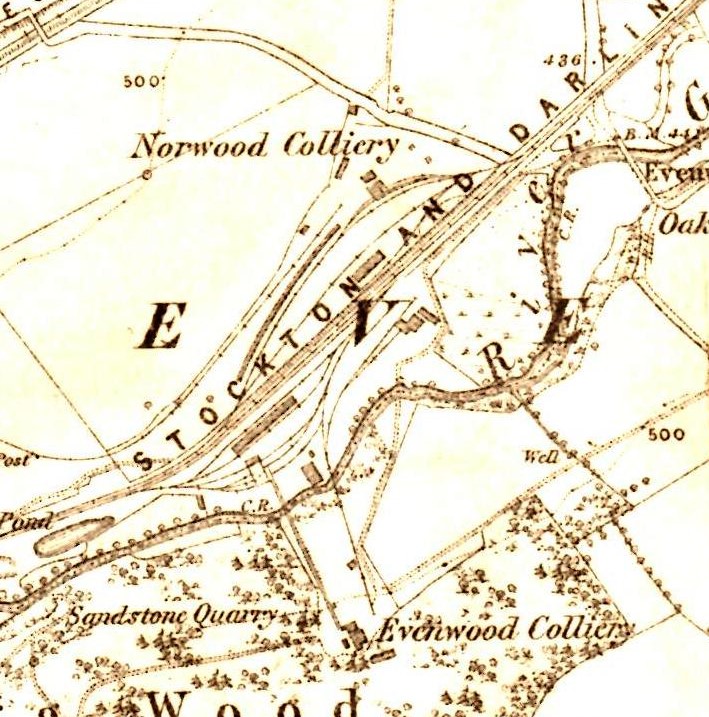

3.5. NORWOOD COLLIERY

The 1859 OS map shows Norwood and Evenwood Collieries and the associated coke works. No buildings are named as brick works.[37]

Above: The 1859 OS map to show Norwood and Evenwood Collieries

From 1872, Thomas Charlton & Co owned Evenwood Colliery. The firm went bankrupt in 1877 and its assets were offered for sale in 1880. It was calculated that the collieries, mines, farms and brick works were worth about £300,000.[38] Bricks marked T.C. & Co. (T. Charlton and Company) have been found locally. The bricks were manufactured at Bitchburn.[39] Thomas Charlton’s son, Edward (1840-1918) lived at Oaks House, Evenwood during the late 1880s and 1890s. The census for 1851, 1861, 1871, 1881 and 1891 contain no entries for men and boys employed in brick manufacture within the Evenwood & Barony Parish. It therefore seems highly unlikely that Evenwood or Norwood Collieries contained a brick works.

4. OTHER BRICKS COMMON TO THE AREA

There are 4 brick companies whose products have been extensively used locally. They are:

- Henry Stobart & Co.

- The North Bitchburn Coal Company

- Pease and Partners

- Bolckow Vaughan & Co.

4.1. HENRY STOBART & CO

Historically, the village of Ramshaw was associated with Henry Stobart & Co. This coal company worked West Tees Colliery at Ramshaw and many drift mines between Ramshaw and Toft Hill and between Ramshaw and Lands. This company’s brick works were established at other collieries such as Old Etherley Colliery, Witton Park and Newton Cap.

4.2. NORTH BITCHBURN COAL COMPANY

Evenwood was associated with the North Bitchburn Coal Company which worked Craggwood Colliery (otherwise known as Storey Lodge), Thrushwood, Tees Hetton, Randolph and Gordon House Collieries. The North Bitchburn Coal Company established brick works at North Bitchburn and later at Rough Lea near Hunwick. The company was taken over by Pease and Partners in 1923. In 1935, the North Bitchburn Fireclay Co. Ltd. was established working from the brick work sites. This company produced firebricks and supplied a range of fireclay and special shaped products. White enamel ware was developed at Rough Lea.[40]

It is doubtful whether any brick kilns were sited at Ramshaw or Evenwood since the census returns up to 1911 record no men or boys employed as brick workers.

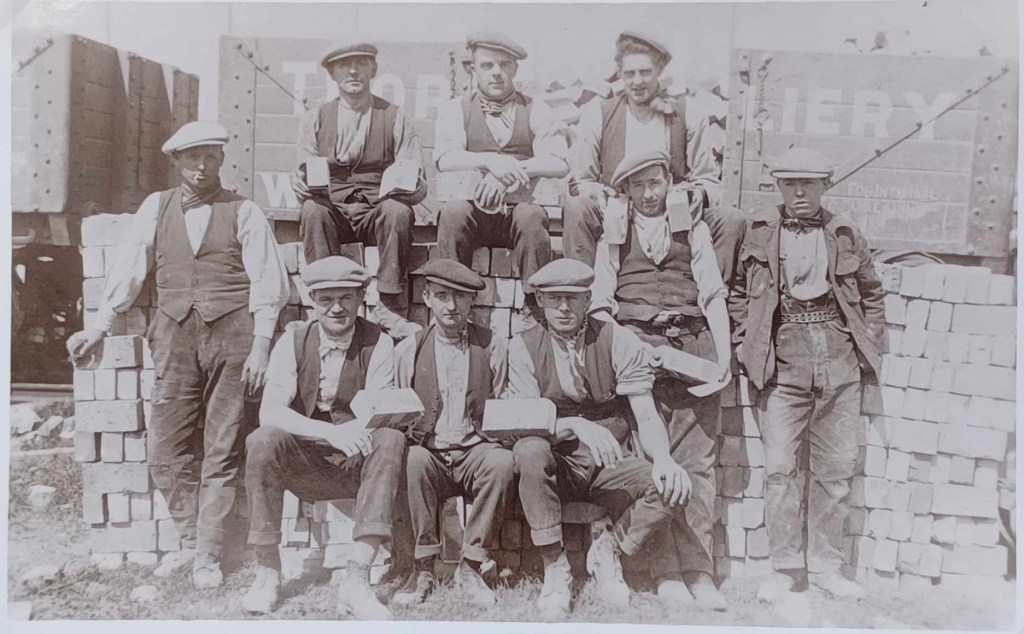

4.3. PEASE & PARTNERS

In 1882, J. Pease and Partners, colliery owners at Bowden Close[41] merged with S.W. Pease & Co., ironstone and mineral quarry owners to form Pease and Partners. It was registered as a public company in 1898. This company was a major employer in south west Durham working collieries, coke works and brick works around the Crook area. The Bankfoot fireclay works at Crook was opened in the 1850s. In a report of 1928, fireclay was brought by an aerial flight ropeway from Roddymoor pit. Up to 7000 bricks per day were manufactured. White facings were manufactured until 1924. The works closed in 1936.[42]

Above: c.1930s Pease & Partners, Bankfoot Brickworks, Crook: A group of workmen[43]

Peases bricks are found throughout the district being particularly associated with railway structures such as the Hownes Gill Viaduct near Consett built in 1856 [44] and a local example is the Gaunless Viaduct. [45] This is sited 1¼ miles west of Evenwood and was an impressive structure as it spanned the River Gaunless and the Haggerleases Branch Railway. This section of the South Durham and Lancashire Union Railway was opened 1st August 1863.[46] The viaduct’s length was 640ft in 4 spans of 120ft with a maximum height of 93ft. The 3 brick piers supported iron girders.[47] Today, only one pier remains, the other 2 were demolished in the 1960s and the debris is strewn across the valley floor.

Above: The Gaunless Viaduct, possibly 1905 when the girders were strengthened

Above: 2024: The Gaunless Viaduct, the remaining brick pier

Above: 2024: A demolished brick pier

4.5. BOLCKOW VAUGHAN & CO

Bolckow Vaughan & Co established an iron works at Witton Park which operated between 1845 and 1884 before moving to Teesside where it developed its iron and steel empire. The company was incorporated 19 November 1864. In June 1920, it acquired a controlling interest in Darlington Rolling Mills and also bought the Eston Sheet and Galvanising Company. In June 1922, Bolckow Vaughan and Co merged with Redpath, Brown & Co. Ltd., constructional engineers based in Edinburgh. The company owned many collieries in south west Durham and operated a number of brick works at Auckland Park, Byers Green, Leasingthorne, Newfield and Witton Park.[48] In November 1929, it amalgamated with Dorman Long and Co Ltd., was wound up and liquidated voluntarily.[49]

In 1947, collieries and 83 associated brick works were taken into public ownership on nationalisation of the coal industry.[50] It is understood that the brick works at Leasingthorne Colliery was under NCB control.[51] Dorman Long & Company Ltd was absorbed into the British Steel Corporation (BSC) upon nationalisation 28 July 1967. [52]

5. THE LAST SURVIVNG BRICKWORKS IN SOUTH WEST DURHAM

By 2000, there were only 2 brick works in the Bishop Auckland area, the Eldon Brick Company and Fosters at Todhills. They underwent numerous “take-overs” before finally coming under the control of the Wienerberger Group. Currently, only the brick works at Todhills is in production. [53]

5.1. ELDON BRICK COMPANY

The manufacture of brick at Eldon dates back to at least 1877 [54] when it worked as part of the South Durham Colliery which was later named Eldon Colliery. Eldon Brick Company was established in 1933 when Eldon Colliery closed. Having outlived the coal mining interests, the brick works survived numerous take-overs,[55] the last being by the Wienerberger group in about 2004, however it closed 24 February 2012. [56]

Above: c.2016 Aerial photo of Eldon Brickworks[57]

5.2. FOSTERS, BISHOP AUCKLAND

Henry Foster was established in the mid-1930s and continued in production until 1979. It passed through a succession of ownerships and into the Wienerberger group, about 2004. Currently, October 2024, this site is the only brick works operating in south west Durham.

——————————————————————————————————————-

Kevin Richardson for the Evenwood, Ramshaw and District History Society – 18 October 2024

APPENDIX 1

SOME BRICKS COMMON TO SOUTH WEST DURHAM

REFERENCES

[1] Much information has come from, “Brickworks of the North East” Peter J. Davison 1986 reprinted 2022 and https://www.brocross.com/Bricks/Penmorfa/Pages/england.htm

[2] Much information has come from, “Coal Mining in County Durham” 1993 Durham County Environmental Education Curriculum Study Group p.181 prepared by P. Davison

[3] Davison p.225 & 226 Ref.6

[4] Davison p.236 by Alec Maughan

[5] 1939 England and Wales Register

[6] The first edition of the Ordnance Survey was surveyed in 1857 and published in 1859.

[7] Davison p.225 & 226 ref.11 New Moors Pottery. There is a post relating to this pottery elsewhere on this website.

[8] Davison p.225 & 226 ref.9 Hilton Tarn brick & tile works

[9] Davison p.225 & 226 ref.8 later called Paddock Mire Pottery.

[10] Davison p.225 & 226 ref.7 Brick & tile works, Evenwood Gate

[11] https://www.brocross.com/Bricks/Penmorfa/Pages/england18.htm#Letter%20P

[12] Richard Robinson has not been traced.

[13] 1898 OS edition

[14] Davison p.225 & 226 ref.8 later called Paddock Mire Pottery

[15] Davison p.225 & 226 ref.8 later called Paddock Mire Pottery

[16] Davison p.236

[17] The site lies beneath the re-routed A688 road which now passes to the east of the former Sun Inn.

[18] Davison p.225 ref:3

[19] Davison p.283 Tow Law & Witton Park

[20] Davison p.283 Witton Park

[21] https://en.wikipedia.org/wiki/Witton_Park_Colliery

[22] “Butterknowle in 1851” 1983 Durham University DACE edited by John Smith p.24

[23] https://en.wikipedia.org/wiki/Witton_Park_Colliery

[24] “Stockton and Darlington Railway 1825-75” undated P.J. Holmes

[25] https://www.brocross.com/Bricks/Penmorfa/Pages/england10b.htm

[26] John Hymer possibly died in 1864

[27] Davison p.283 Cockfield

[28] https://www.brocross.com/Bricks/Penmorfa/Pages/england18.htm#Letter%20P

[29] Christopher Wilson (c.1834-1904) was recorded as a brick maker between 1851 and 1881, living most of the time at Howle. He cannot be traced for the year 1891 and by 1901, then aged 68 he was a lodger, living on his own means.

[30] William Parkin (c.1831-1906) was recorded as a brick maker in 1851, 1861 and by 1871 he was a labourer in the brick yard. By 1881, he was a farmer and did not return to the industry.

[31] Davison

[32] There is some debate whether these chimneys belong to the brick works or the coke works.

[33] https://www.brocross.com/Bricks/Penmorfa/Pages/england4b-6.htm

[34] Davison p.226 map

[35] “Butterknowle in 1851” 1983 Durham University DACE edited by John Smith p.54-57 and “Cockfield in 1851” 1977 University of Durham Historical Association Annual Vacation School (Prof Batho)

[36] We cannot confirm if there was a brick manufacturing works at this site.

[37] Davison p.226 and ref.5

[38] Daily Gazette for Middlesbrough 6 January 1880

[39] Davison p.283

[40] Davison p.218 – 222

[41] This colliery was near to Helmington Row, between Crook and Willington

[42] https://www.brocross.com/Bricks/Penmorfa/Pages/england18.htm Note: Other sources state 1935

[43] Photo courtesy of Brian Featherstone

[44] “Memories of the LNER South-west Durham” 1989 Allan W. Stobbs p.26

[45] Also known as Lands Viaduct

[46] “The Stainmore Railway” 1973 K. Hoole p.37

[47] Hoole Appendix 3 p.120

[48] https://www.brocross.com/Bricks/Penmorfa/Pages/england4a-2.htm

[49] https://discovery.nationalarchives.gov.uk/details/r/5721aaa1-6082-4cde-9e64-669fffc048dd

[50] https://en.wikipedia.org/wiki/National_Coal_Board

[51] https://www.brocross.com/Bricks/Penmorfa/Pages/england16.htm

[52] https://co-curate.ncl.ac.uk/dorman-long-and-co-ltd/history/

[53] September 2024

[54] DCC Planning Report

[55] Ambion, The Brick Business and Turka/Wienerberger

[56] Julie Hall

[57] https://htare.co.uk/news/former-eldon-brickworks-site-is-sold-for-900k/