The Key Dates are set out below:

1895, The North Bitchburn Coal Company Limited sunk the colliery and was responsible for constructing the coke works. There were 60 Coppee coke ovens, the cost was £13,000 and they were built by Belgian bricklayers.

1897, a second set of 20 coke ovens was constructed by Evans, Copper & Co. under the able management of Daniel Davis.

1898 15 April: An Account of the Coke Ovens at Randolph Colliery

By the courtesy of the chief agent of the North Bitchburn Coal Co., Mr. C. Widdas of Beechburn Grange, the members of our club

visited Randolph Colliery, near Evenwood, on April 15 1898. This account is an extract from “Transactions of the Weardale Naturalists Field Club” Part 1 Vol.1 1900 pp91-96 by John Barker [Manager of Rogerley Quarry for Pease & Partners]

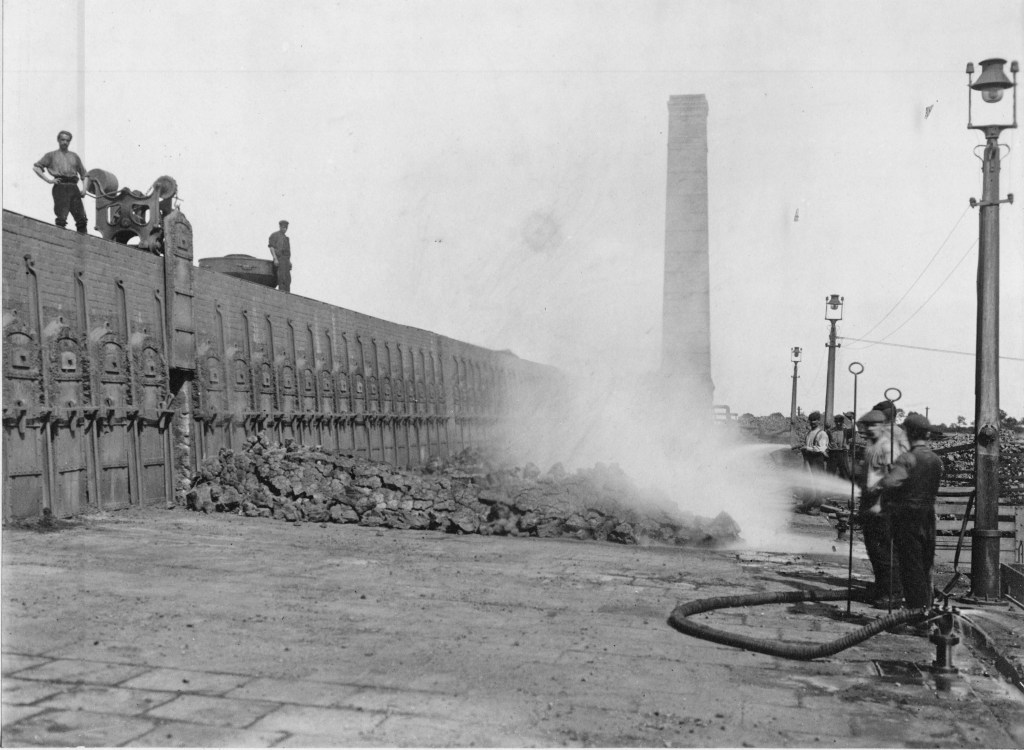

“The coke ovens, of which there are 84 in number, are about 30 feet long, 7 feet high and 2 feet wide and each when charged holds 6 to 7 tons of washed coal and is provided with 3 circular openings at the top to facilitate an equal or level charging. After being thoroughly closed for 48 hours, the temperature reaching 2,000 degrees Fahrenheit, it is converted into a coke of very good quality. When drawing a charge, the doors are lifted by a crab and a mechanical ram forces out the charge, consisting of about 4 tons. The miniature Vesuvius was soon cooled by a plentiful supply of water (supplied again from pit pumpings) and a hose pipe to direct the steam and in a short time was placed in trucks, which are standing conveniently and thus made ready for market. The average production is about 1,000 tons per week.

The gasses from the ovens are collected into a flue at the end and in part is conducted to 2 boilers at the other end of the ovens. They are thus always supplied with heat at a regular temperature and, with very little attention, require no other fuel. The air supply to the ovens is conducted from the ends and is therefore warmed before entering the ovens. The steam generated at those 8 boilers supplies all the mechanical force necessary for the pit-top requirements and to drive the fan, which is a Waddle, 30 feet in

diameter, keeping a good ventilation throughout the underground workings. It also drives the dynamo for the electric lighting plant.

The washing plant is the Luhrig patent, the coke ovens by Coppée, were built by the patentees and are lined with best Scotch silica bricks. Both departments do credit to those who invented them and to the company and officials who have adopted them for use. The old rule of thumb method has no place here.”

Below: 1898, a map to show Randolph Colliery and the location of the coke ovens

Below: An image from the Durham Miners Association Randolph Lodge banner. The banner was officially unfurled June 1909. It shows the 2 colliery shafts, the coal screens, the rail yard for incoming and outgoing trucks and to the right, the coppee coke ovens with coke resting on the bench being loaded into the coke trucks below.

Below: Almost the same view but to taken from the loading bench.

Below: On top of the battery, 3 loaded coal tubs awaiting the removal of the oven lids, to fill up the oven.

Below: The released coke being cooled down by spraying with water

Below: A group of Randolph coke men in front of the ovens.

1909: All the coke men were given their notices when the company decided to replace the existing coke ovens with a new battery of 50 patent bye-product ovens.